The possibility to increase the apparent strength of glass considerably by the tempering process is crucial in order to utilize it for load-carrying purposes. The process of tempering glass has been known for more than a century, however, quantifying the effect of temper stresses in more complex geometries has only been possible for a decade.

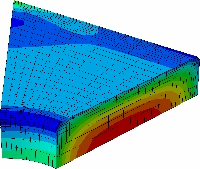

The spatially dependency of the residual stresses entail a spatial dependent apparent strength. This means that the strength properties near edges, corners and holes are different from what can be seen far from these.

A model for predicting such stresses in complex geometries has been developed and used for analyzing e.g. plates with bolt holes.

|

|

|

|

|

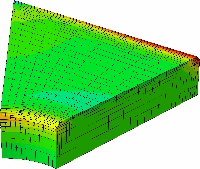

At the beginning of tempering. Transient stresses along the edge.

|

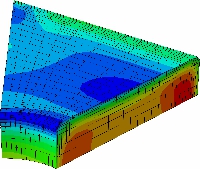

During tempering, compressive zone is growing.

|

After tempering, the final residual stress state with compressive stresses at the surface.

|

Due to the high level of residual stresses in tempered glass, tempered glass has a very characteristic failure mode, where it fragmentize completely. This has been experimentially observed using digitial high-speed cameras (Nielsen et. al. 2009). These investigations also revealed never before reported phenomenons and determined the speed of the fragmentation front to 1466m/s with an estimated accuracy of less than 1%.

|

|

Video showing the fragmentation of tempered glass.

|

References

Nielsen, J.H., Olesen, J.F. and Stang, H., The Fracture Process of Tempered Soda-Lime-Silica Glass., Experimental Mechanics 2009, 49(6): 855-870.